Delivering Smooth Surfaces for Demanding Fabrication Needs

Achieving a flawless surface is critical in modern metalworking, especially when quality and efficiency are non-negotiable. A Dross Removal Machine for Sheet Metal plays a central role in this effort by eliminating unwanted slag and contaminants that result from cutting processes. This equipment ensures that sheet metal surfaces are clean, uniform, and ready for further processing, reducing the risk of defects while boosting the overall aesthetic and functional value of each component.

Precision Cleaning for Consistent Quality

Metal fabrication operations rely heavily on clean and accurate components. A Dross Removal Machine for Sheet Metal guarantees precise removal of slag and spatter without damaging the base material. This level of consistency is essential for industries such as automotive, aerospace, and construction, where even minor imperfections can compromise product integrity. With uniform cleaning results across batches, this machine supports the production of parts that meet tight quality standards every time.

Increased Throughput with Automated Debris Removal

Time is a valuable asset in manufacturing environments. A Dross Removal Machine for Sheet Metal significantly reduces manual effort by automating the cleaning process. This translates into faster turnaround times, higher throughput, and streamlined production lines. By minimizing labor dependency and cutting down on secondary operations, manufacturers experience fewer delays and lower costs while maintaining optimal surface quality for subsequent welding, painting, or coating applications.

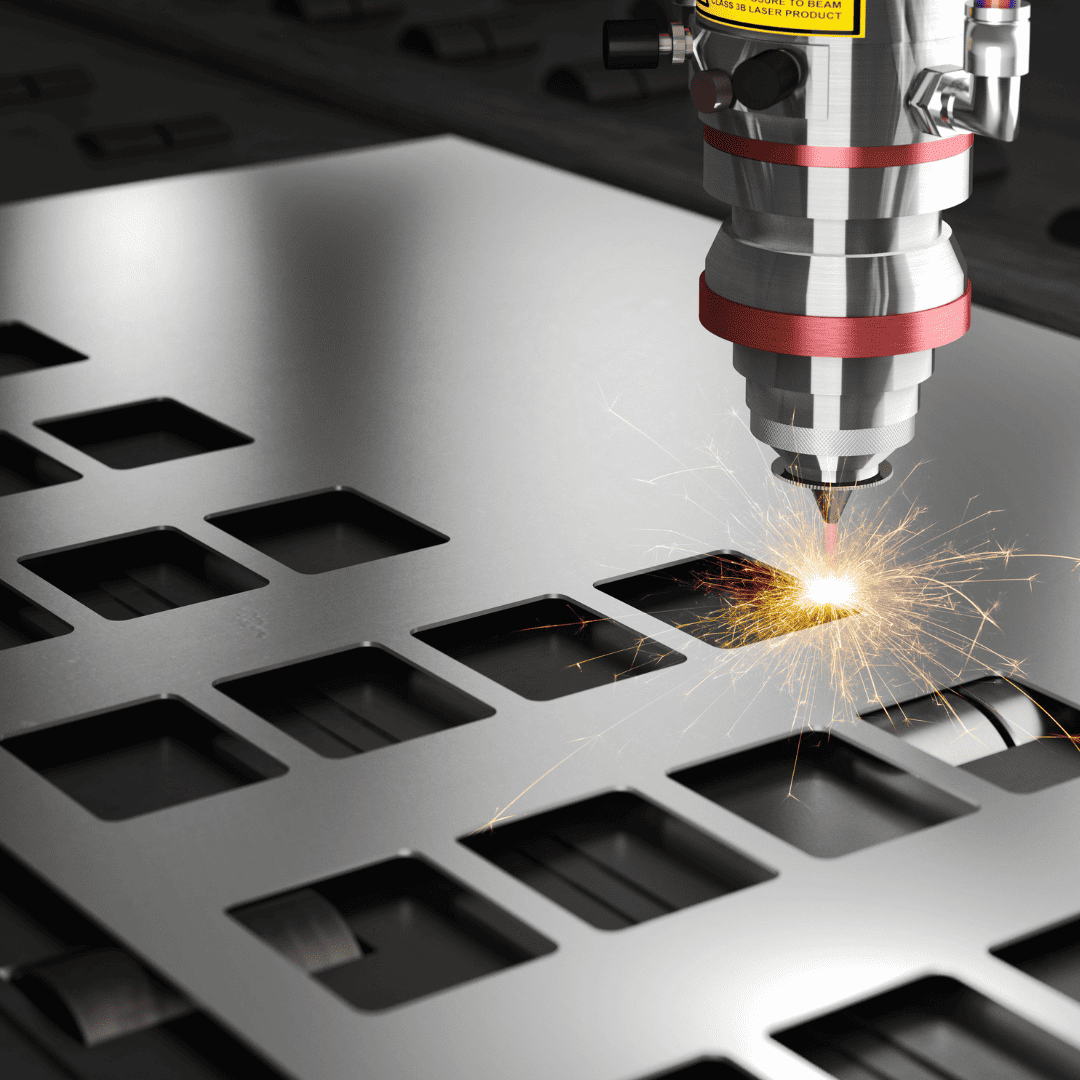

Essential for Laser and Plasma Cut Components

Cutting sheet metal using laser or plasma often results in dross accumulation along the edges. If not properly removed, this residue can interfere with part assembly, appearance, and corrosion resistance. A Dross Removal Machine for Sheet Metal effectively addresses this issue, delivering smooth, burr-free edges that improve fit and function. The machine’s versatility makes it ideal for handling a variety of profiles and thicknesses, ensuring edge refinement that supports long-term product performance.

Enhanced Safety and Reduced Rework

Using a Dross Removal Machine for Sheet Metal not only improves surface quality but also enhances workplace safety. Sharp slag deposits can cause injuries during manual handling, and improperly cleaned components can result in faulty assemblies. By eliminating dross at the source, this machine helps prevent such risks and minimizes the likelihood of product recalls or rework. The result is a safer working environment and greater confidence in production reliability.

Designed for Durability and Operational Efficiency

Built to endure continuous use, a Dross Removal Machine for Sheet Metal is engineered for strength and operational excellence. With features like heavy-duty rollers, robust cleaning brushes, and advanced motor systems, the machine handles rigorous cleaning tasks with ease. The durable construction ensures long-term reliability, even under high-volume conditions. Designed for minimal maintenance and consistent output, it stands as a dependable solution for sheet metal processing facilities aiming for long-term success.

Boosting Surface Readiness for Finishing Processes

Clean sheet metal is essential for downstream operations like powder coating, galvanizing, or assembly. A Dross Removal Machine for Sheet Metal ensures that each sheet enters the next stage free of slag, improving adhesion, electrical conductivity, or mechanical bonding. This smooth surface finish enhances the overall visual appeal and functional characteristics of the final product, supporting client satisfaction and brand credibility across various industries.

Aligning with Modern Manufacturing Demands

Today’s production lines require more than speed—they demand repeatability, automation, and surface perfection. A Dross Removal Machine for Sheet Metal aligns with these evolving standards by integrating smart controls and user-friendly interfaces. With adjustable settings for pressure, feed speed, and material type, the machine accommodates a range of applications while maintaining consistent results. Its adaptability helps manufacturers respond to diverse project needs without compromising on productivity or quality.

Conclusion: A Vital Asset for Metal Fabricators

In the pursuit of precision and efficiency, a Dross Removal Machine for Sheet Metal proves indispensable. It enhances surface finish, minimizes manual labor, and contributes to a smoother workflow throughout the fabrication process. Whether preparing components for structural assembly or final cosmetic treatment, this machine plays a crucial role in achieving superior results. For manufacturers looking to stay ahead in a competitive market, investing in a Dross Removal Machine for Sheet Metal is a strategic step toward improved productivity, higher standards, and lasting performance.